DM has several common facilities for both research and teaching, besides the facilities distributed across the eleven research labs in the department. Some of the key common facilities include the Smart Factory, Teaching Labs, Virtual Design Studio (VDS Lab), Protics Lab, Wet Lab, Legacy Workshops, CPDMed-TBI Las, DESIC Innovation Centre, SHYAM facility and D-CoE.

The IISc Smart Factory, a Common Engineering Facility Centre (CEFC) at DM, IISc, under the SAMARTH Udyog Bharat 4.0 program, is a testbed with both automated and manual platforms, aiming to bridge the gap between conventional and cutting-edge manufacturing technologies. The following are the facilities available:

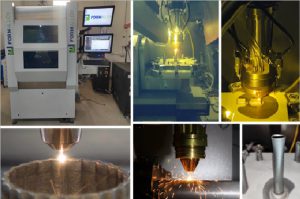

Metal Additive Manufacturing Machine at IISc Smart Factory

Metal Additive Manufacturing Machine at IISc Smart Factory

Fibre Laser Cutting Machine at IISc Smart Factory

Universal 5 Axis CNC Milling Machine at IISc Smart Factory

Legacy Machines at Smart Factory

Wire Discharge Machining Facility at IISc Smart Factory

The facility houses three polymer 3D printing technologies—FDM, MSLA, and MJP supporting functional prototyping, research, and product development. It is a shared resource available to both the IISc community and external users.

Fused Deposition Modelling (FDM)

Masked Stereolithography (MSLA)

Multi Jet Printing (MJP)

The facility includes a 2 m Portable CMM (±27 μm accuracy) for precise 3D inspection and a Vision Measurement System (150 × 100 × 200 mm, 2.5 μm accuracy) for high-precision optical measurement of small parts. It also houses a 25 kN Universal Testing Machine with ±30 mm stroke for reliable tension, compression, bending, and cyclic material testing.

CMM

VMS

UTM Machine

The Foundation for Science Innovation and Development, IISc in association with the Department of Innovation and Technology, Government of Karnataka, has established a MedTech & Geriatric Healthcare Technology Business Incubator (CPDMED TBI) at the Department of Design and Manufacturing (DM), IISc, Bengaluru. The establishment facilitates innovation and entrepreneurship and invites innovator entrepreneurs for developing and realisation of their ideas from hatching and nurturing through to commercialisation. The following are the facilities at CPDMeD:

|

Testing |

Incubation facilities |

|

EMI/EMC Testing |

Hatchery |

|

Usability Testing |

Ideation space |

|

Environmental Testing |

Designer space |

| Medical Simulation Facility | Maker space |

|

Mechanical Testing |

Conference room |

| Chemical and Biological Testing Facility |

|

As part of the Centre for Excellence in Smart Hybrid Additive Manufacturing (SHyAM), we have established a Cold Metal Transfer (CMT)-based Wire Arc Additive Manufacturing (WAAM) unit utilizing the KUKA (KR 20 R1820-2 E) robotic arm and Fronius (TPS 500i) power source. Due to the inherent advantage of the WAAM process, it is capable of a high deposition rate that can be utilized for faster fabrication of components, whereas the robotic arm allows for the deposition of complex structures.

The robotic arm and power source integrated setup for CMT-WAAM

The Indian Institute of Science (IISc) Bengaluru, in collaboration with the Government of Karnataka, has launched the Design Centre of Excellence (D-CoE) to transform the state’s design and innovation landscape. The D-CoE will function as a nodal agency supporting Karnataka’s vision of becoming a national hub for design and Industry4.0. As a “School of Practice for Design”, the centre bridges the gap between academia and industry, providing critical hands-on training to students, startups, MSMEs, and corporates. Recognizing the high failure rate of startups due to challenges like insufficient innovation and lack of market-fit products, the D-CoE leverages IISc’s expertise to address these barriers. With IISc’s history of success in fostering startups and its robust design research leadership, the D-CoE focuses on imparting design thinking, prototyping, and business development skills essential for driving innovation and enhancing the success of new ventures.

Softwares:

NX CAD – Software

RIHNO 3D – Design software

Keyshot– Rendering software

Clip Studio Pro – Digital Artwork Software

Hardwares:

Bench Grinder

Goat Robotics – AGV ROBOT

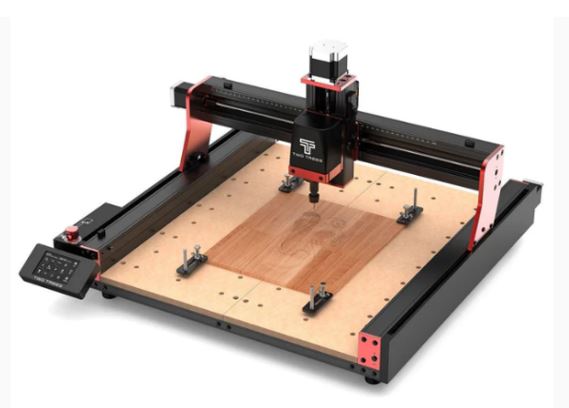

TTC450 Pro CNC Woodworking Engraving Machine

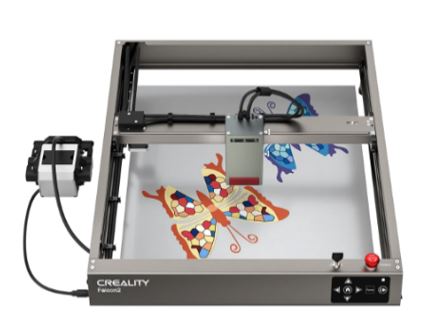

Falcon2 40W Laser Router

Clay Printer

Jigsaw machine

Klin Machine

Potter Wheel Machine

Bech Drill

Sewing machine

Airless Spray-Painting Machine

Clay Bot Dual Pro – Clay 3D printer

Arbitrary Function Generator

Digital storage Oscilloscope

Multimeter

DC Power Supply

Protocol Analyzer

Baincut LSS – Low Speed Cutting Machine

Digital Goniometer

Digital Weighing Machine

Grip Strength Tester

3D scanner

Digital Stadio Meter

Height Adjustable Stool

Digital vernier

Outside Pistol Caliper

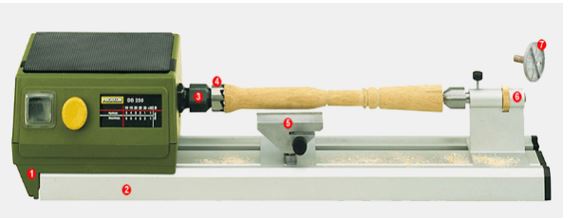

Wooden lathe Machine

ESAb Cutmaster 120- Plasma Cutting Machine

MIG TIG Welding Machine

Artist Pro 19(Gen 2) Drawing Display

Artist 16 Drawing Display (2nd Gen)

1-DoF Manipulator (Haptic)

Content Creation Room Facility:

Raman Hall: Collaborative class room space:

With the help of the FIST grant, the capabilities of the RIMM Laboratory have been considerably enhanced in the area of Lightweight Materials Manufacturing through the addition of following resources:

- Environmental Chamber – for conditioning of composites (Figure 6)

- Mechanical Stirrer – for mixing resins (Figure 6)

- Sonicator – for ultrasonic mixing (Figure 6)

- Compression molding machine for making polymer composites laminates (Figure 6)

- Autoclave – for curing composites (Figure 6)

- Vacuum Bagging Setup – for making defect free high quality composites

- Advanced Computional Design Facility consisting of a multi-core HP server with client workstations hosting state-of-the-art design and simulation tools comprising Catia, Delmia and Abaqus

Resources in Lightweight Materials Manufacturing procured through the first instalment of the FIST grant for DM, IISc

Computer hardware for the Advanced Computational Design Facility set up through the first instalment of the FIST grant