Research Highlights

The problem of detecting spatial and non-spatial conflicts across multiple functional design domains has been addressed. A key requirement for this is the representation and extraction of empty spaces (ES) in the product. A method has been developed for identifying and decomposing open spaces from the CAD model. New elements have been defined in SysML to model the product structure, empty spaces, product lifecycle states, and design domains. These elements are then used to capture product knowledge and integrate it with the CAD model of the product and the empty spaces identified. Procedures have been developed to construct a fully associative model of the product and the empty space, linking geometry to product knowledge such as requirements, product lifecycle states and design domains. This model enables the detection of spatial conflicts.

Two approaches were developed and implemented to detect spatial conflict. The first, a graph-based approach, works by finding cycles in a graph of ES blocks, requirements and design states using a standard single destination pathfinding algorithm. The second method uses a matrix-based representation of the problem space in the form of a DMM. The approaches have been compared based on ease of implementation and visualization. The graph-based method is easy to comprehend but challenging to implement for spatial conflict detection compared to DMM.

DMM also provides a clear and compact visualization compared to the graph-based method. The DMM used also enables inference of global metrics and relations. DSMs for ES blocks can be created with the constructed DMM, grouping ES Blocks based on requirements allocations. Similarly, a requirement DSM can be inferred from the DMM for any product lifecycle state and provide a dashboard for requirements engineering. Spatial conflicts are computed for every requirement allocated to an ES block providing real-time information to designers across domains as the design progresses. However, the conflict resolution is left to the designers to resolve. Respective design domains are highlighted for every spatial conflict.

An octree model to represent to detect and represent spatial conflicts across multiple design domains has been developed. The octree model offers a few advantages over the use of the CAD system in both detection and visualisation of the ES blocks in conflict. The octree model also detects conflicts arising due to the movement of parts and constraints imposed by physical phenomena. A framework has been developed to create an octree model linked with intended empty spaces in the product associated with design requirements, product lifecycle states, functional design domains and physics-based constraints. The octree model identifies regions available free from conflicts, which designers can recommend for locating new parts in an assembly and carrying out layout planning. The methods have been implemented using CAD APIs, SysML and C#.

Figure 1 a) 3D solid model of part embedded in a universal box b) Cut section model of bulk empty space decomposed into intended Empty space blocks to be allocated to different design requirements c) ES Blocks depicting multi-domain spatial conflicts in CAD model d) Parts representation in green, ES blocks having at least one requirement allocated shown in orange and ES blocks under spatial conflict across multiple design domain shown in red using octree-based voxel model e) Multi-domain spatial conflict representation using Octree Voxel model by rendering conflicting ES blocks in red with wireframe SWS octree voxel model outside CAD environment using OpenGL.

(Alternate caption – Empty space modelling and multi-domain spatial conflict detection using octree models)

Option 1

More information contact: Prof. B Gurumoorthy, PLM Lab

Option 2

2-3 references

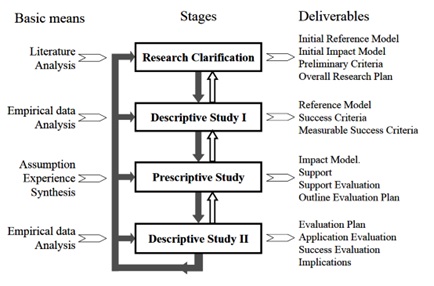

Design research (Research into Design) develops knowledge about design phenomena to inform and improve the practice and education of design. A design research methodology is a framework for carrying out design research effectively and efficientl. In order to bridge a major gap in the availability of an appropriate design research methodology DRM was initiated in 1991 (along with Lucienne Blessing and Ken Wallace) and developed (with Lucienne Blessing) into an extensive framework by 2009. DRM has four stages (see Image): Research Clarification (clarify goals and success criteria for research), Descriptive Study 1 (understanding influences on success), Prescriptive Study (developing design support to improve appropriate influences), and Descriptive Study 2 (evaluate design support for the expected improvement). DRM has been used extensively around the world for carrying out design research, at Masters, PhD and project levels (over 2600 Google Scholar citations); it is taught for two decades at the European summer programme for Design Research and at the Indian Summer School for Design Research. It is also taught in several teaching programmes (Politecnico di Milano, Italy, Blekinge UT, Sweden; TU of Catalonia, Spain; IISc, India; IIT Ropar, India, and others).

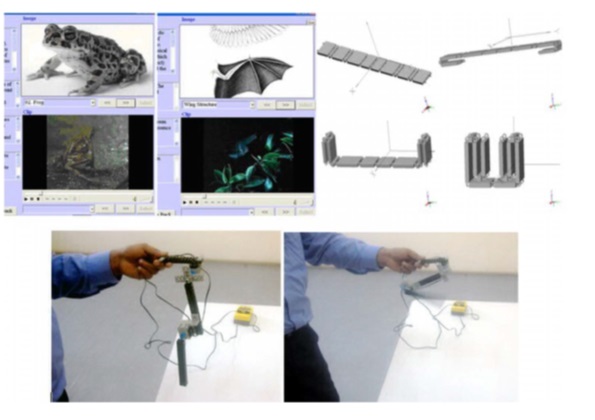

Biological systems and processes have always been a source of inspiration for designers. However, the inspirations have traditionally been acts of serendipity rather than within a systematic process. Biologically Inspired Design (BID) is a relatively recent discipline that explores how information on relevant biological systems can be used as analogical sources of inspiration for design ideation. Work at CPDM developed Idea-Inspire, world’s first computational tool for supporting biologically inspired design ideation. The tool has a database of entries, each with information on one biological or engineered system, structured using a powerful ontology called ‘SAPPhIRE’ model of causality. SAPPhIRE stands for State-Action-Part-Phenomena-Input-oRgan-Effect, which were empirically found to be the seven constructs used by engineering designers to design engineered systems. The model can be used to explain in a structured way as to how a system, biological or engineered, works. Fragments of information from an explanation of such systems work can be used as stimuli to inspire ideation of novel systems, e.g. avoidance of sonic boom in tunnels by high speed trains by using kingfisher beak as stimulus. SAPPhIRE model has been used extensively around the world for understanding engineering design processes, developing measures for creativity, structuring in-flight use aircraft manuals (Pratt & Whitney) and aircraft maintenance manuals (Rolls-Royce), and for structuring the entities in Idea-Inspire. Testing of Idea-Inspire with designers revealed a 2-3 times higher Ideation fluency when it was used as support. The work has been published AI EDAM, Res. Eng. Design, ASME JCISE, J of Knowledge Management, etc.

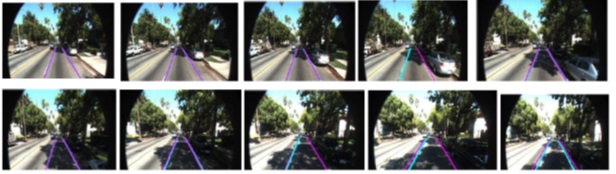

This research aims to develop real-time computer support for robust Lane detection (using camera output), which can work well under complex scenarios including, lighting variation, shadow contamination, partial/fully occluded lanes with dense traffic (Figure below). Lane detection consists of online processing of capturing video/image of road lane marking, lane modelling, feature extraction, lane detection, lane tracking as given in the figure below.

Further, to improve driver’s direct visibility, the dashboard and door design is modified for Volvo Truck India and is being tested virtually in static condition. Then driver visibility will be tested virtually as per the guidelines. Another effort focuses on creating Indian virtual road environment based on AR/VR to study the driver’s behaviour on driving simulator.

In addition to this, another program is under development for simulating how truck driver will see pedestrian or vulnerable road users (VRUs) through direct and indirect vision.

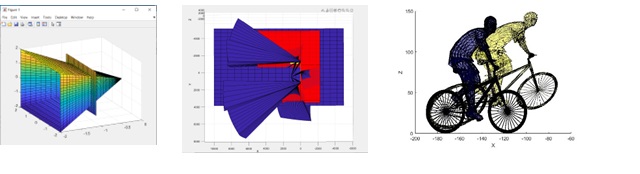

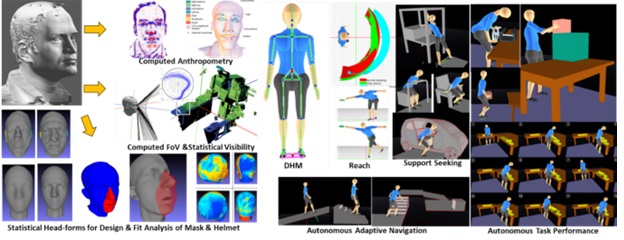

Ergonomics aims to make products and work environment safe and comfortable for human users. Empirical evaluation is the norm but it expensive and error prone. The advanced Digital Human Modelling (DHM) framework developed support systematic, computational, and objective methods for measurement and simulation-based assessment of work scenarios viz. product fitment, statistical visibility, autonomous human performance studies etc. The DHM consists of body, eyes, and hand models. The publication on computational determination of facial landmarks was one of the most downloaded papers during the first few months of its publication. The vision model computationally determines the user’s field of view (FoV) and composes a statistical FoV for a population from 3D head scans for biofidelic visibility analysis. The body is an articulated anthropomorphic structure capable of autonomous statically balanced posturing, navigation, and task performance viz. ingress-egress and mechanical assembly. The autonomous task performance capability with object handling and navigation is one of its kind in literature. A high degree of naturalness in the performance has been achieved which enabled assessment of difficulties and identification of critical phases through simulation. The research on DHM has been funded by ADA, Boeing and ISRO during 2006-2018. The work has been published in ASME Journal of Computing and Information Science in Engineering, Computer-Aided Design, and Theoretical Issues in Ergonomics Science journals.

The complex eyes in humans do not only support a complicated visual system but also work as an excellent medium to express affective states. Charles Darwin in his book The Expression of the Emotions in Man and Animals written in 1872, indicated a correlation between widening and narrowing of eyes with emotional states. In the first decade of 19th century, Redlich [1908] and Westphal [1907] related pupil dilation with physical task demand, or even thinking of physical task, while Hess [1975] reported change in pupil dilation with respect to viewing of photographs. The research team at I3D Lab worked on estimating cognitive load for aircraft pilots and automotive drivers. Detection of drivers’ cognitive load is a well-investigated subject in Automotive Technology. Recent advancement of information technology added a plethora of infotainment system inside a car to help the driver. However, proper and also improper uses of those systems often distract the driver from driving and lead to driving accidents. Besides the infotainment system, the change of mental states of driver due to road or traffic condition, duration of driving can also increase chances of accident. Detecting cognitive distraction is challenging as it is often not explicitly expressed by drivers and can only be detected through estimation of cognitive load. In automotive, we developed a driver behavior monitoring system based on physiological parameters in real driving situations under various ambient lighting conditions and traffic participants. For aircraft pilots, we designed and developed a low-cost virtual reality (VR) based flight simulator with cognitive load estimation feature using ocular and EEG signals. Our study also involved four test flights in BAES Hawk Trainer and Jaguar aircraft performing various maneuvers between 20,000 ft to 8000ft. We collected ocular parameters from both pilot (Pilot in Command) and co-pilot (Observer Pilot) in the aircraft, using the same set of equipment used in the simulation study and compared ocular parameters during different phases of flight like take-off, cruise, maneuver and landing phases. We found the number of fixations significantly vary between pilot and co-pilot during take-off, maneuver and landing phases and also found significant correlation between number of fixation rate with rate of descent during air to ground dive training missions and with normal load factor (G) during constant G level turn maneuvers. The study was covered in New Scientist magazine and resulted multiple papers and international patent applications with industry and defense organizations. Presently the research team is working with ISRO human space flight center to improve the internal layout of the Gaganayan crew module.

Figure: Anti-clockwise: Driving scenario in automotive, Snapshot of HMI evaluation dashboard, VR flight Simulator: hardware Setup (left), visual rendering on HMD on ground (right top) and during target tracking (right bottom)

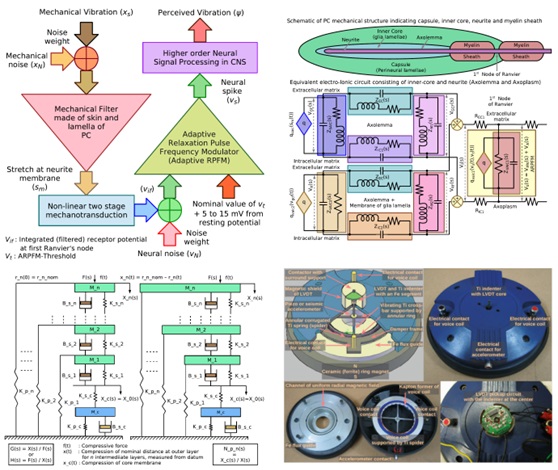

Haptics is an interdisciplinary field of study related to touch sensation. Among the five major sensation (touch, taste, smell, hearing and sight) touch is the most robust and fundamental creating the basis of the reality. Therefore, creating different type of high fidelity artificial touch stimuli is still a topic of research and extremely challenging mainly because of:

1) Haptic system is highly distributed,

2) High fidelity quasi-static haptic stimulus needs ground reaction force,

3) It needs strong active sensing and

4) Involves distributed energy source for bi-direction interaction.

Work focuses mostly on fundamental research on haptics that leads to technological development towards high-fidelity haptic stimulus generation for different applications in the field of biomedical engineering, virtual reality (VR), industrial training, manufacturing, education technologies and personal interaction. Besides applied research the core research activity covers the field of electronics and instrumentation engineering, psychophysics and sensory-physiology at macro and micro level covering experimentation and modeling of biological haptic systems. The work has been published in Haptics IEEE Transactions Journal and Eurohaptics conferences.

Major accomplishments in this area include the following:

- Developed formulations for linear and geometrically nonlinear analysis of stiffened plates.

- Developed new particular integrals for gravitational and centrifugal body force analysis, and thermoelastic analysis of most general 2D and 3D anisotropic solids by the boundary element method.

- Developed an automated matrix method for dimensional analysis.

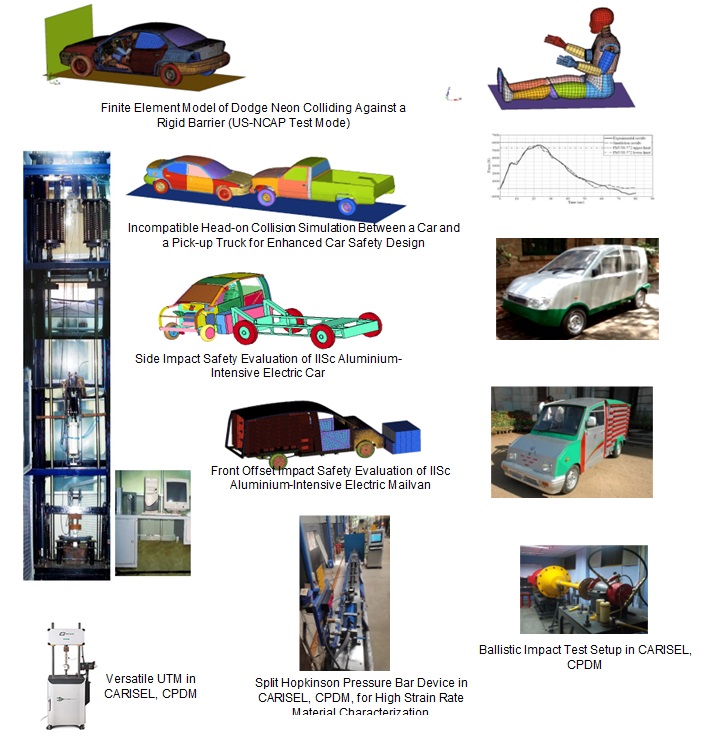

- Derived the first nonlinear analytical solutions for a single degree-of-freedom lumped parameter model with a bilinear elastoplastic spring attached to a rigid wall and a mass at either end, with the mass being imparted an initial velocity towards the wall. The model was utilized for providing the most definitive proof that a minimum crush space of around 30 mm is required for protecting targets against head injury on the upper interior of a vehicle for conforming to the FMVSS 201 standard.

- Reduced the weight of production Mahindra & Mahindra Scorpio SUV by developing a new CAE (Computer-Aided Engineering)-based procedure involving size and topology optimization.

- Developed improved and accurate crash simulation procedures for Tata Motors resulting in industry-leading five-star vehicles such as Tata Nexon, Tata Altroz, etc. in crashworthiness and occupant safety.

- Developed new insights into the behaviours of adhesively-bonded joints with steel substrates under varying loading rates and temperatures.

- Developed a new and highly efficient “Practical Multidisciplinary Design Optimization” technique for lightweighting of vehicle body structures meeting NVH, Durability and Crash Safety requirements.

- Harnessed the power of CAE in the form of explicit nonlinear finite element analysis towards developing vehicle crash safety testing procedures which are more economical and representative of collisions between incompatible vehicles such as cars and pickup trucks

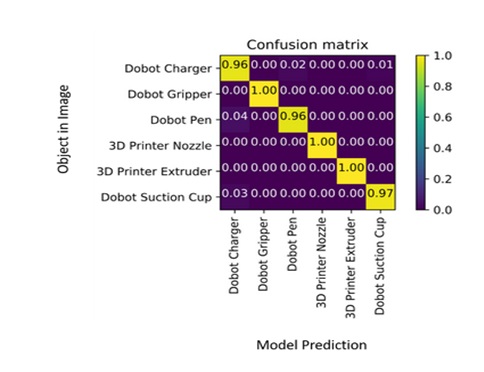

Realizing automatic inventory management in warehouses needs to efficiently identify items. Barcodes and RFID tags are traditional approaches to solve this problem, but both suffer from limitations. This research involves a 2D camera vision-based method using a deep convolutional neural learning network to sort different items stored in a warehouse for the purpose of inventory management. Employed method ResNet-50 uses a combination of residual learning and deep architecture parsing called residual network architecture. Running at 4 frame per seconds (FPS) it can achieve a high accuracy of 98.94% on the dataset created by authors consisting of 1450+ images of machine parts, by utilizing data augmentation and transfer learning making it suitable for other real-time applications as well. It achieved high accuracy of 98.94%on the dataset created by the authors. It is presently implemented on a multifunctional 3 DoF robotic arm for validation. More advanced deep learning frameworks such as Mask RCNN is under testing to perform the task of classification, localization and segmentation using a single network in an smart industrial environment. The work has been reported in IEEE ICRA, IEEE/RSJ IROS, ICCAS and other major conferences, and received a best paper finalist award.

Network Architecture of CNN used in the proposed method

Architecture, Engineering and Construction (AEC) projects often face cost and schedule overruns, and quality concerns. The project management challenges in AEC projects are believed to emanate from complex socio-technical dependencies between the products, processes, people and policies, which tend to vary with each project, with each discipline and project team, with each phase of the project, and with regional variations in bylaws and ways of working. One of the ways to address these systemic interdependencies is to leverage digital technologies that can provide a multidisciplinary collaboration platform (Singh et al. 2011). Building Information Modelling (BIM) tools and methods, together with other digital tools and approaches, can provide the digital infrastructure to improve the performance of construction projects and the construction industry (Singh 2019). Some of the key contributions in this research include the development of a framework for BIM as a collaboration platform (Singh et al. 2011), the discussions around the BIM ecosystem and technology adoption (Singh and Holmstrom 2015, Singh 2019), the emphasis on BIM for facilities management (FM) (Yalcinkaya & Singh 2019), the emerging discussions on Digital twin in AEC (Agrawal et al. 2022), and a System-of-Systems approach for situation awareness in BIM-enabled construction projects (Mirzaeifar & Singh 2020). This stream of research emphasizes the systemic dependencies and the coevolution of products, processes, people and policies. The BIM Collaboration Platform framework proposed by Singh et al. (2011) is among the top-cited papers on Building Information Modelling, with over 825 citations.

Figure: Recursive development cycle for technology adoption and enhancement (Singh et al. 2011)

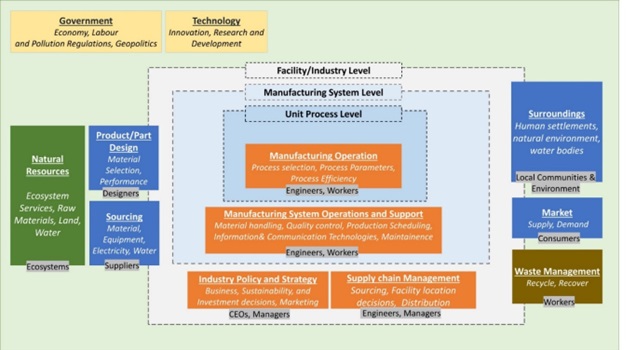

The research activities involve the following:

- Developing and testing a novel framework for sustainability assessment in manufacturing. The work adopts a multi-stakeholder systems approach and examines effective approaches to sustainability assessment, dealing with the product impacts traced to design and manufacturing. Specific emphasis has been on geographically charactering and tracing product life-cycle impacts, accounting for active impacts occurring during the use and disposal phase of products. One of the novel contribution has been in defining ‘sustainable manufacturing processes’ which has been cited by the latest European Environment Agency technical report on ‘Circular Economy and Biodiversity’ (ETC CE report 2023/7).

- Developing a novel framework for energy neutrality assessment for integration of smart sensors in buildings. This work involves specialisations from both buildings and product design and examines the role of energy-saving sensors in buildings and its effective integration for reduction in the life-cycle energy and resource footprint (net-zero).

- The work has been reported in Sustainable Manufacturing – Handbook in Advanced Manufacturing (Elsevier), Frontiers in Sustainability Journal, and . Sustainable Energy Technologies and Assessments Journal.

Fig: Levels of manufacturing, decision-makers (gray shaded) involved and their roles, and surrounding entities affecting manufacturing operations

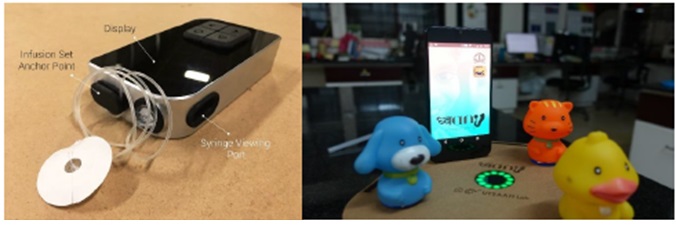

The work focuses on designing and manufacturing socially relevant medical product innovations to enable affordable and accessible healthcare in resource-constrained settings. The approach starts from real-world problems directly observed in the clinical setting, following the systematic design process stages, and ends with delivering technically superior yet affordable solutions. Design and Development activity in the laboratory covers various medical technologies: e.g., Intravenous drip monitoring, Foetal Acoustic Monitoring, Secure Ultrasound, Insulin Pump for T1DM, Integrated hearing-aid and speech therapy solution. Each project has strong clinical connections via renowned doctors from hospitals like St Johns Medical College, KC General Hospital, MSR Hospital, and Narayana Health; and are based on unmet needs directly observed in clinical settings in India.Two of the key projects and their outcomes are highlighted below:

InsuFlo: Automated Insulin Delivery Device: Following the user-in-the-loop design process, we developed a highly affordable yet state-of-the-art insulin pump for type-1 Diabetes patients. User-in-the loop approach connects with users throughout the design process, including during requirements capture, ideation, prototyping, and testing phases. The prototype device employs a novel (patent pending) actuation mechanism that eliminates the need for expensive components yet achieves the delivery accuracy of stateof-the-art insulin pumps. Further, we designed a novel shape memory actuator-driven bi-stable mechanism to meet the space constraints for a compact pump. These mechanisms can have broader applications in other compact medical devices. Clinical evaluation of the prototype is scheduled for 2023. The project was part of a larger IMPRINT project on the development of an artificial pancreas (3.6Cr over 3 years, Co-I) and has received Gandhian Young Technology Innovation award, Biotechnology Ignition Grant and additional funding for further development (82L for 2 years). The product was selected for ISHOW India award by ASME, ‘Most Promising Innovation’ award at D-Tech Conference and well received by diabetes healthcare professionals at Diacare Conference 2022.

Left: Function Prototype of InsuFlo automated insulin delivey device

Right: Dhwani app with connected response system toys

Dhwani: We have developed a novel system for technology-enabled speech therapy for children with hearing impairment (HI). Most children with HI fall back on their developmental goals without effective speech therapy and cannot integrate with mainstream society. Following a similar user-in-the-loop approach, the team has identified barriers to accessing speech therapy and developed a system for capturing responses from children with HI on a mobile platform to conduct speech therapy at home. The system enables close monitoring of the progress of the speech therapist remotely. We carried out a clinical investigation involving parents of over 50 children with HI in collaboration with St. Johns Medical College, Bangalore, and the Parents Association of Deaf Children, Mysore, to judge the usability of the mobile platform and connected toys over six months. We presented preliminary results at the Global Humanitarian Technology Conference and plan to conduct further clinical studies in the near future to measure this approach’s effectiveness. This work started as a course project and subsequently obtained funding from BIRAC-PACE scheme and NIDHI Prayas scheme (51L over 2.5 Years) to initiate further research for developing an open-source hearing aid system with integrated speech therapy provisions.

We wish to translate these results into clinical practice and investigate what enables innovation in the medical device development space as a design research topic. We identified challenges in medical device innovations via formal interviews of industry stakeholders and data analysis. Since medical product innovation requires the coming together of multiple disciplines, we have identified the role of collaboration and its effectiveness as possible areas of future design research. The work has resulted in the development of a seven-stage medical device innovation framework.

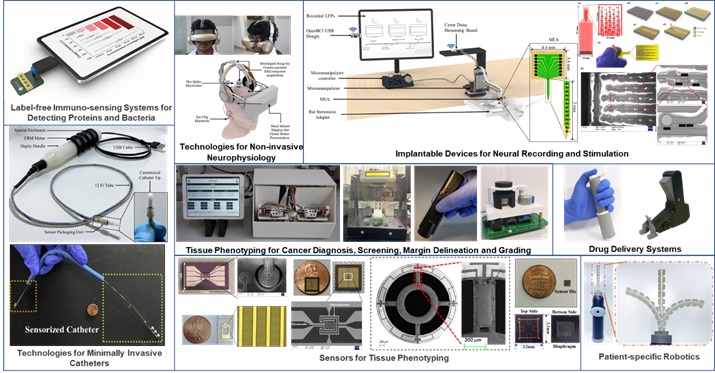

Work in this research led to the following:

- Development of a point-of-care testing platform for rapid and accurate detection of the SARS-CoV-2 virus utilizing a lab-on-PCB-based electrical immunosensing approach. The approach enables quick and efficient disease control and management during the COVID-19 pandemic.

- Development of algorithms for automated detection and classification of seizures. The algorithms analyze interictal EEG signals for precise and timely seizure diagnosis and have the potential to revolutionize epilepsy diagnosis and treatment.

- Development of a flexible microelectrode array and silicon-based microneedles for precise recording of electrocorticography signals. The indigenously fabricated sensors facilitate high-quality neural signal recording in rodents for understanding diseases like epilepsy, Parkinson’s disease, etc. The devices can also be used to understand the functioning of different brain regions in a more detailed way by providing the ability for neuromodulation and recording.

- Development of MEMS-based force sensors for catheter contact force measurements. The research focuses on the fabrication, packaging, and proprioceptive force recognition of a susceptible tri-axial piezoresistive micro-force sensor. Integrating the sensor into cardiac ablation catheters can potentially improve cardiac ablation procedures for arrhythmia by providing accurate force measurements and haptic feedback.

In the recent past we have worked on and developed the following main products:

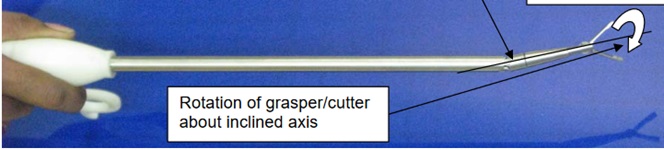

Articulated laparoscopic tool – The enhanced flexibility of operating a laparoscopic tool with articulation, similar to that available in a wrist, is achieved by addition of a joint at the end. The existing degrees of freedom of the tool, namely three translations and one rotation, are not affected. Additionally, due to the joint used, the force experienced by the surgeon when the tool touches an organ is not affected. A picture of the novel laparoscopic tool is shown below.

LifeBox – An active heart perfusion container with temperature control. Most existing devices can effectively preserve an organ for transplant for about 4 hours. Together with Prof. B Gurumoorthy & Prof. Manish Arora and students and starting from a course in computer aided product design, a system was developed which could extend the preservation times during transport for transplant to 6 — 8 hours. The device is under development for commercialization.

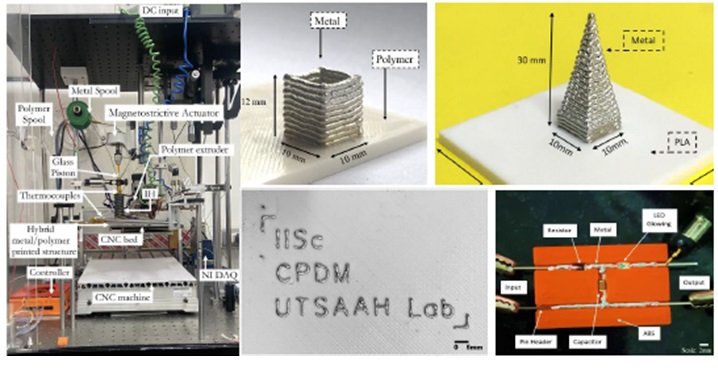

Manufacturing research in my lab focuses on low-temperature metal additive manufacturing and its combination with polymer additive manufacturing to create metal-polymer hybrid structures and functional electronics from a digital design. We developed a novel magnetostrictive actuator-based metal droplet-ondemand printer (patent pending) that creates sub-millimeter metal droplets at the desired locations. This system uses an efficient zero-voltage switching circuit-based induction heat for melting the metal. A metal structure can be built with the above technology, and the same can be integrated with polymer additive manufacturing such as Fused Deposition Molding, to create functional electronics directly from the digital design. The printed metal track provides electrically conducting pathways, and the polymer provides isolation and base material for building the device. Placement of electronics is currently done by manually pausing the printing process in the middle but can be automated in the subsequent versions of the system.

Other ongoing projects at the UTSAAH laboratory include:

- Subcutaneous Adipose Tissue thickness measurement using ultrasonic elastography.

- High frequency (>15MHz) pMUT probe for intraoperative imaging during neurosurgeries

- Mixed tissue ultrasound phantom for research into intra-operative guidance

- In-process mitigation of warpage in polymer 3d printing

- Laser melting of tin-based alloys for making electrically conducting tracks

Figure: Experiment setup of Hybrid Metal Polymer Additive manufacturing system and some fabricated structures including functional electronic device